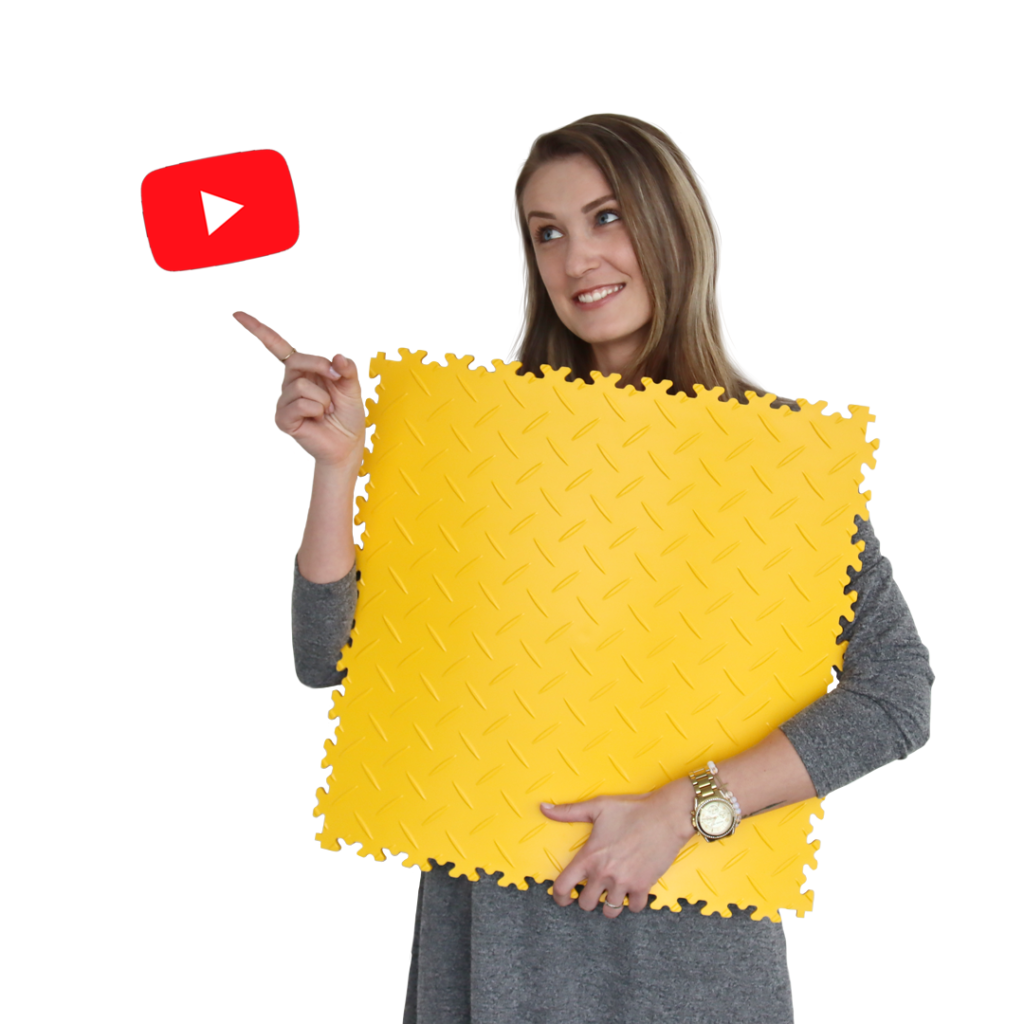

Production of Fortelock tiles from A to Z

Would you like to know how is the Fortelock floor made ? You may already have one in your garage or in your business. The whole production takes place exclusively in Czech Republic at the Fortemix s.r.o. headquarters in Paskov.

Tiles are made from plastic granules, which change from solid state to liquid state after a heat treatment.

Thanks to an injection molding machine the material then travels at a temperature of 180 ° C into a mold where it takes the shape of a tile. After the tile has been formed, the product is cooled down so that it can be removed from the mold by an automatic manipulator and placed on a conveyor belt for final cooling.

PVC material properties

The PVC material from which the tiles are made from is chemically resistant to acids, salts, alkalis, oils and alcohols. Thanks to the quality of the material and the honest production, the floor is durable and safe for various production plants, buildings, warehouses, but also for homes, offices and school premises.

Ecology

Fortelock tiles are 100% recyclable. Production generates a minimum waste and emissions. 50% of the tiles production is from recycled production scrap, which is crushed with our own crushers, as well as from purchased waste. Thanks to our own recycling, any failed products do not leave the factory and are soon back in production.