PVC also does well as industrial tiling

Whether you run an industrial warehouse or car repair shop, the floor in big halls always plays a major role. It should be easy to clean, handle large workloads, and last a long time. Unlike other alternatives, PVC floor tiles meet all these requirements.

Anyone preparing to repair an industrial floor should first think about what type of repair is actually worth it. It’s not just about the price, but many more important aspects should be considered. Concrete floors can be renovated in different ways and the ones most often used include installing PVC floor tiles and an epoxy coating.

They must withstand loads and chemicals

Forklifts move around in manufacturing halls, heavy machinery stands there, and material is often stored on the floor. In the case of PVC floor tiles, it’s necessary to go for a type designed for heavy loads, which can seamlessly handle heavy-duty operations for more than ten years. Most companies produce this type, and Fortelock has a tile for enormous workloads, namely Fortelock Industry. It’s color remains steadfast the whole time and its polymeric structure makes it resistant to most oils and acids. It’s enough once in a while to wipe the floor down with some soap, water and a mop.

With regards to resistance, an epoxy floor has absolutely different qualities, making it very popular in many plants. In comparison with other types of floors, it’s cheap and it can even be represented with the company logo. However, it’s not too well-suited for plants where forklift trucks could be driving about, or even automobiles. The narrow wheels of the forklift truck are a problem for it, and the heavy weight and hot tires of cars damage it by causing it to flake, and chemicals stain it. If you do not choose an anti-slip finish, you will have a problem with a slippery surface. You won’t have this with PVC floor tiles, which are always manufactured with rough surfaces.

The installation should be easy, and repairs as well

The bigger the hall, the bigger its coverage – not only in terms of material, but also work. The time needed to install the floor plays a role in how long operations in the hall must be interrupted. Epoxy floors usually require three layers (resin penetration, self-leveling layer, and then the epoxy resin). The first one should dry for 24 hours and you must wait a similarly long time after applying the final layer. And as soon as it happens that in some part of the hall the coat begins to crack, the entire floor must be redone.

Store Fortelock floor tiles in the warehouse

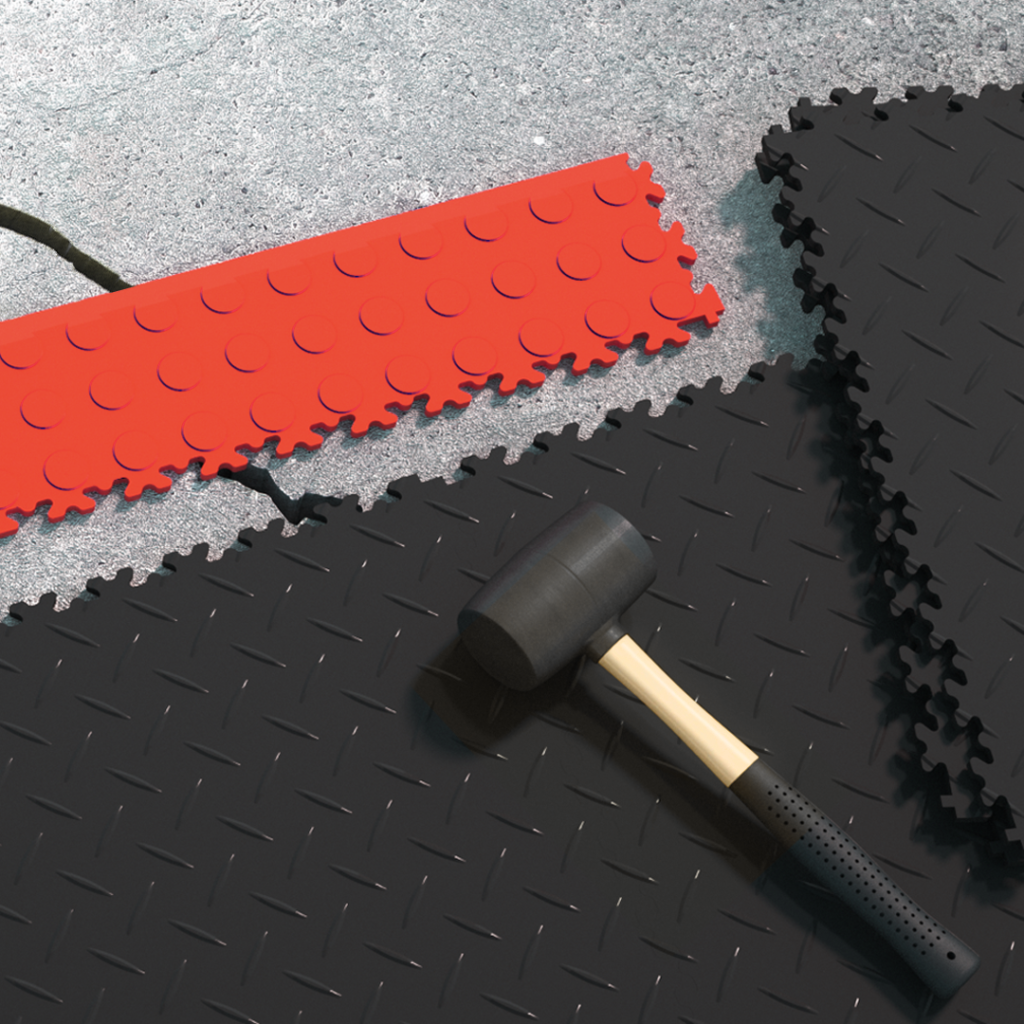

Installing PVC floor tiles is considerably simpler by comparison. The tiles should be placed in the room 24 hours prior to installation in order to become room temperature and no other work needs to be done with them. In the case of an uneven surface, a self-leveling compound needs to be used, holes and cracks filled in, and it’s good to add a cement screed in damp spaces. The self-leveling compound dries in just a few hours. We now come to the variety of tiles that only need to be laid and not glued; the entire process is very fast. No drying is required, so there’s no need to wait. And if by chance one of the tiles becomes broken, it’s no problem to change it individually.

Floating tiles made of PVC can be found in industrial halls more and more. The advantages are obvious and the disadvantage practically only one – the higher price. Everyone must decide for themselves whether the investment is worth it.