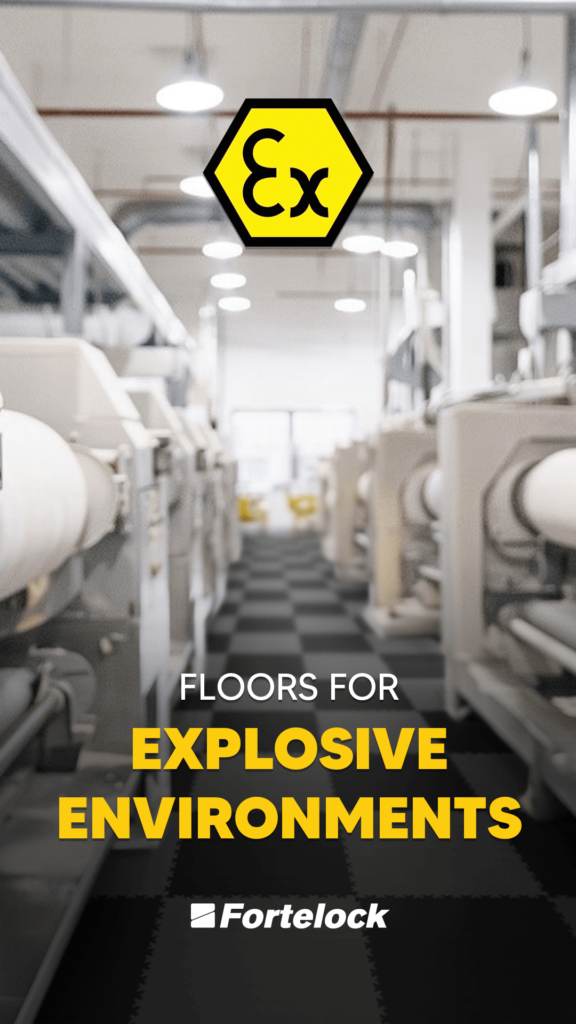

Conductive Flooring: Safe Solutions in ATEX Environments

Facilities that operate in explosive environments face unique safety and security challenges for employees and equipment. One critical factor is choosing the right flooring to minimize the risk of dangerous situations. What should be considered when making a choice?

Explosive Environments

The risk of explosion applies to all sites and operations where an explosive atmosphere can arise. An explosive atmosphere is created when hazardous substances in the form of gases, vapours or dust mix with air. Such a mixture can ignite under certain conditions (when there is neither too much dust, so the fire does not have enough air to burn, nor conversely too little, so there is nothing to burn) and cause enormous damage.

The risk of explosions is not confined to refineries and chemical plants, but also arises in places you might not expect. Such premises include the food industry, especially mills, grain warehouses, sugar production and flour warehouses. The same goes for the pharmaceutical industry, where volatile chemicals are used to produce medicines, and the textile industry, where synthetic fibres are produced or textiles are just handled.

In all of these areas, there may be a situation where there is a certain amount of dust or gas in the air that can be ignited by even a small spark in the form of static discharge. An innocent spark that would normally only give a person a tiny “shock” when touching a door handle can cause tremendous damage.

How to Minimize the Risk of Electrostatic Discharge?

Electrostatic discharge occurs when too much electrical charge builds up in the human body. Did you know that the human body can be charged up to 35,000 volts? Walking on a carpet or plastic floor or handling a plastic bag can charge you with up to 10,000 volts. Even at a charge of about 7,000 volts, contact with conductive material produces a spark that could be fatal in explosive atmospheres.

You can, however, effectively minimize the risk of charge being generated by installing a conductive floor. Good ones serve two purposes:

- Efficiently dissipating the electrical charge to the building’s ground

- Preventing the accumulation of electrical charge on a worker

The materials from which the floor is made must meet specific requirements for electrical conductivity and mechanical and chemical resistance to ensure safety and reliability of operation.

Key Criteria for Flooring Designated for Explosive Atmospheres

- Antistatic and conductive properties:

– The floor material must be capable of dissipating electrostatic charge to prevent its accumulation and the generation of sparks.

– The electrical resistance of the floor should be between 106 and 109 ohms for dissipative floors and less than 106 ohms for conductive floors. - Mechanical resistance:

– Must be sufficiently strong and wear-resistant to withstand operational loads and prevent damage that could compromise safety. - Chemical durability:

– Must be able to withstand chemicals that may be present in the environment to prevent material degradation and maintain its properties. - Non-sparking material:

– Must be designed not to produce sparks even when subjected to mechanical impact or wear

Common Materials for Flooring in Explosive Atmospheres

- Antistatic epoxy resins

Epoxy floors with antistatic properties are a less common solution in industrial environments. These floors are easy and simple to clean, but less durable and very difficult to repair if damaged. Their disadvantage is the need for a perfectly prepared surface, in addition to which their production is time-consuming and requires special machines, which is reflected in the high purchase price.

- Antistatic vinyl coverings

Vinyl floors are mostly resistant to chemicals and mechanical wear. The installation of vinyl strips 2 metres wide is usually more complicated and requires that the space be empty, which in the case of renovation is tedious and increases the cost of the renovation itself. In addition, full adhesion is required, making it impossible to move it to other areas. In the case of leased premises, its removal entails higher costs associated with the return of the premises to their original condition.

- Antistatic or conductive PVC tiles

PVC tiles with antistatic properties provide good protection against electrostatic charges and are resistant to chemicals and mechanical damage. They are easy to clean, can be quickly and easily replaced if damaged, do not require adhesives and are usually laid easily. Their installation is possible during full operation, which saves the cost of clearing the area and the necessary shutdown of production/traffic. In the event of a relocation, the tiles can be disassembled and reassembled at the new location.

- Special concrete mixes

Concrete floors can be treated with antistatic additives or surface coatings to provide the required electrical properties and mechanical durability. Their application is demanding in terms of precision and workmanship and requires professional installation.

Conclusion

Floors intended for explosive atmospheres must be made of dissipative or, preferably, conductive materials that are resistant to mechanical wear and chemical agents. Using the right materials and adhering to the relevant standards is key to ensuring safety in such environments.

Tip for Professionals – Know the Standards

The ATEX Directive (ATmosphères EXplosibles) is a framework of European Union legislation governing the safety of products, protective systems and equipment intended for use in potentially explosive atmospheres. These regulations are intended to minimise the risk of explosions of flammable gases, vapours or dust in industrial environments.

Harmonised standard EN 60079-0 Explosive Atmospheres defines the how to meet the requirements of the ATEX Directive for the safety of electrical equipment and protective systems intended for use in potentially explosive atmospheres.

This standard is an important part of the implementation of the ATEX Directive as it provides the exact technical requirements that must be followed under the European legislation. Manufacturers of electrical equipment and protective systems must comply with the requirements of this standard in order to comply with the ATEX Directive and to place their products on the market within the European Union.

Specific requirements for floors are defined in the following guidelines:

- EN 60079-0 and EN 60079-15: These standards set out general requirements for electrical equipment and protective systems in potentially explosive atmospheres. They are also concerned with the electrical properties of conductive floors and their ability to dissipate electrostatic charge.

- EN 1081: This standard specifies the requirements for the electrical resistance of floor coverings, which is a key parameter for conductive flooring. It defines procedures for measuring electrical resistance and determines the required values within safe parameters.

Contact our experts for more information, technical specifications or an individual offer. We are ready to help you find the best floor solution to meet the specific requirements of your industrial space.