How Much Does a Floor Renovation Cost? Price versus Actual Cost

How Much Does a Floor Renovation Cost?

Price versus Actual Cost.

When we buy a new product, we always want to know the price first and foremost. Whether it’s electronics, clothing or home renovation, the decision often comes down to which option is cheapest. However, the true value of a product is about more than the price tag. Transportation, installation, maintenance or the lifetime of a product have a major impact on how much we ultimately pay. For example, when choosing a car, the base price may be tempting. But other costs such as servicing, the cost of spare parts, the service network or fuel consumption can affect our decision.

A similar dilemma arises when choosing flooring solutions. Are you considering a floor renovation and deciding between installing Fortelock PVC tiles or a new epoxy floor? At first glance, the cost of Fortelock tiles may look much higher than that of epoxy. What are their real costs if we take into account all hidden costs?

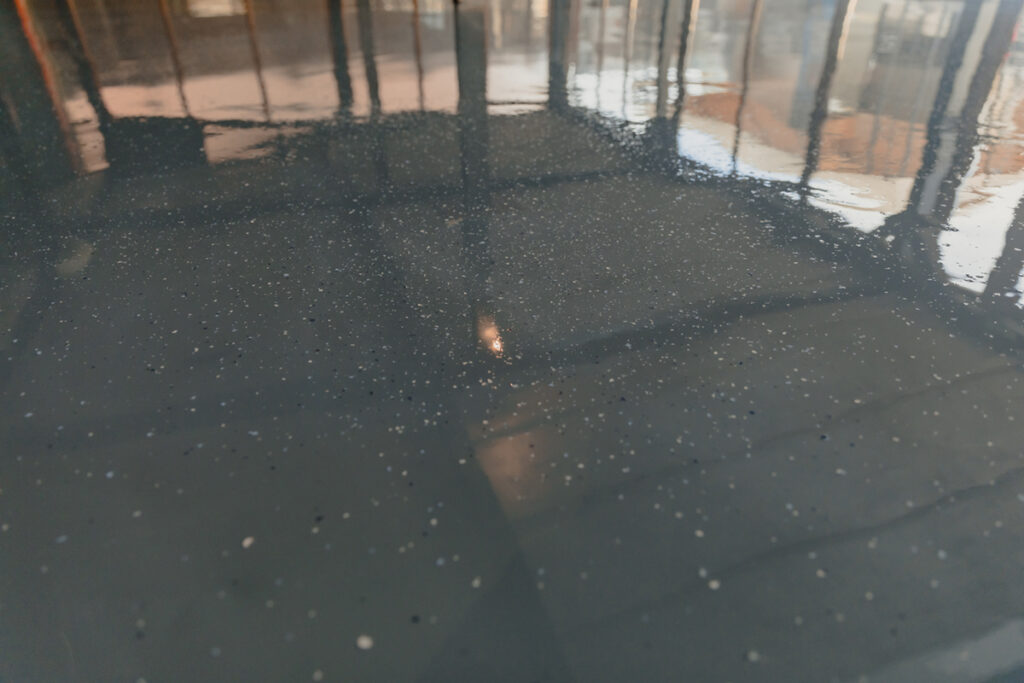

Epoxy floor: Durability and Aesthetics

Epoxy flooring, also known as decorative resin, produces a smooth, hard, chemical-resistant surface. It is suitable for production halls, warehouses and areas where high load capacity is a priority. In addition, it offers aesthetic range thanks to a wide choice of colours and effects.

However, the substrate for epoxy flooring must be perfectly flat, strong, clean and dry. Achieving such a surface can be a problem, especially during renovations. It is therefore particularly suitable for new premises where the owner can ensure perfect subfloor flatness.The substrate must be almost perfectly dry – no more than 3% substrate moisture content. That’s because epoxy is not vapour permeable, so escaping moisture could cause bubbles or cracks in the floor. This makes it unsuitable for cellars, damp garages and storage areas.

Epoxy coating is not recommended for use on contaminated areas, such as service stations or garages where vehicle fluids have been spilled. The epoxy would not hold on such a surface and would start to crack over time. Application on wooden substrates is also not recommended. Wood is constantly working, which could cause the surface layer to crack. On the other hand, epoxy floors provide many design options. There are plenty of additives that help create a floor to suit the tastes of the owner.

Application procedure for an epoxy flooring

- Perfect preparation of the substrate – filling cracks and holes, sanding bumps, drying of moisture and extraction of dirt.

- Penetration coat under epoxy coats.

- Final layer – two or three layers with a total thickness of 4–6 mm.

- Curing time about 5–7 days.

Advantages of epoxy floor:

- Lower material costs: The price for the material is often lower than for PVC tiles.

- Resilience: Suitable for high loads.

- Smooth, seamless surface: The surface is smooth and seamless, making it easy to maintain.

Disadvantages of epoxy floor:

- Difficult installation: It requires professional installation, substrate preparation and several days of curing (5–7 days).

- Interruption of operations: During installation, the space must be emptied, which often leads to major losses.

- High demands on the preparation of the base layer: The substrate must be flat, dry and clean. It is not recommended for damp areas.

- Limited possibility of local repairs: Damage often requires a complete recoating.

- It is not a thermal insulator: Epoxy flooring does not have insulating properties and feels colder.

Fortelock PVC Tiles: Practicality and Flexibility

Fortelock PVC tiles are a modern solution with easy installation and minimal maintenance. They are designed to be laid without a specialist and allow for quick use without interrupting operations. The “click” system makes it easy to snap together without glue or any special tools. This allows installation without the help of experts, saving time and money.

The tiles are extremely resistant to mechanical stress, chemicals and moisture. It makes them suitable for use in tough environments such as workshops, warehouses and garages. If a part becomes damaged, it can simply be replaced without having to repair the entire floor. Also, the surface is low-maintenance and easy to clean. In addition, the tiles are often made from recycled materials, which is a plus for those seeking a more ecological solution. Although Fortelock PVC tiles offer many advantages, they do have their disadvantages. One is the higher initial investment compared to some traditional flooring solutions. Tiles are also less suited for areas with high temperatures, where they require gluing.

Advantages of Fortelock PVC Tiles:

- Quick and easy installation. The tiles can be easily laid without any special skills, saving time and installation costs.

- Flexible solution for operation: The tiles can be laid while operation is underway, which is ideal for premises where every hour of interruption is costly.

- Possibility of immediate use: Once laid, the tiles are immediately ready for use, preventing further costly downtime.

- Easy to maintain and replace: You can easily replace damaged tiles without affecting the rest of the floor.

- Environmental aspect: the tiles are made from recycled materials and can themselves be recycled, which is good for the environment.

Downsides of Fortelock PVC tiles:

- Higher initial investment: Material costs can be higher than for epoxy floors.

- Temperature sensitivity: In areas with large temperature fluctuations, the tiles need to be glued.

Cost Comparison: Smaller Space vs. Large Warehouse

To get a better idea, we compared the installation costs of Fortelock PVC tiles and epoxy floors in two model cases – a garage (20 m²) and a large warehouse (500 m²).

Garage 20 m2

| Floor type | Material costs (price incl. VAT) | Installation costs | Total installation time | Total cost |

| Epoxy coating | €10-15 per m² | €20 per m² (in case of professional installation) | 5–7 days | €600 |

| Fortelock PVC Tiles | from approx. €40 per m² | €0 (own installation) | 2–3 hours | €800 |

epoy floor

Warehouse 500 m2

| Floor type | Material costs (price incl. VAT) | Installation costs | Total installation time | Interruption of operation | Lost profit | Total cost |

| Epoxy coating | €7 per m² | €20 per m² (in case of professional installation) | 7–14 days | complete | High – depending on turnover | Depending on turnover; more than €25 000 |

| Fortelock PVC Tiles | Individual price | €0 (own installation) | 1–2 days | none, can be done in stages | €0 | €17 000 |

Epoxy floor or Fortelock?

When choosing a floor, it’s important to consider the specific needs of your space. Fortelock PVC tiles are ideal for those looking for fast installation, minimal disruption and flexibility. Epoxy floor, on the other hand, are attractive for their aesthetic look, seamless surface and lower material costs.

Each solution has its advantages and disadvantages. Make an informed decision and choose a floor that suits your needs and budget.